This is the third in a series of articles on the most important steps to take when assessing and improving your home’s energy efficiency. So far, we’ve focused on the blower door test and air sealing. In this article, we’ll review the next step: insulation.

At Pearl Certification, we’re a remote-first team, which means I get to see my colleagues in their homes nearly every day via web conferencing. When our Marketing Director Deanna started a couple months ago, I began to notice she’d appear in different rooms over the course of the day. I asked if it was a change of scenery she was seeking in her journey from home office to living room to bedroom and back. “No,” she said, “I’m following 70 degrees around my home!”

In the first two articles in this series, we discussed the importance of properly sealing your home against leaks and the incursion of outside, non-conditioned air. This impacts respiratory health, energy efficiency, cost to heat and cool, and, just as important, the comfort of your home. For the growing pool of remote workers like my colleagues at Pearl, it’s also a question of productivity and a healthy working environment, which brings us to the crowning jewel of a properly sealed home: attic, basement, and wall insulation.

Unless your insulation is brand new (and certified), there’s a good chance it will come up as part of the air sealing discussion with your contractor. Contractors typically perform air sealing prior to modifying insulation, which means they get a really good look at existing insulation as they search for breaches underneath. What they find may spark a conversation about the age of the home, when the original insulation was put in, where it was put in, and how it’s been performing to date.

One of the first — and most important — terms you’re going to hear from your contractor is “R-value.” While technical jargon can seem intimidating (and building science is full of them), R-value is pretty simple: It’s the measure of thermal resistance of any two-dimensional barrier. For example, your comforter has an R-value. So do your windows and the sheetrock in your walls. The higher the R-value, the greater the barrier’s resistance to the flow of heat through it.

Since heat moves from where it’s warmer to where it’s colder, reaching minimal R-value is critical for keeping heat in your home in the cold months and out of your home in the warm months.

When it comes to the R-value of insulation, contractors typically calculate the total R-value of the installed insulation by multiplying the R-value of the material by the number of inches of that material present. So if a specific type of insulation has an R-value of 2 per inch, and your goal is to have a total R-value of 38 wherever there is insulation in your home, you’d need 20 inches of that insulation to achieve your target.

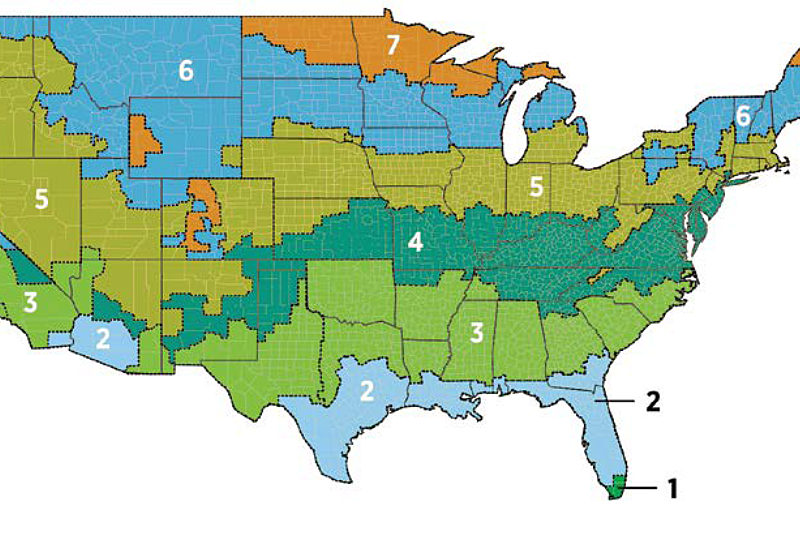

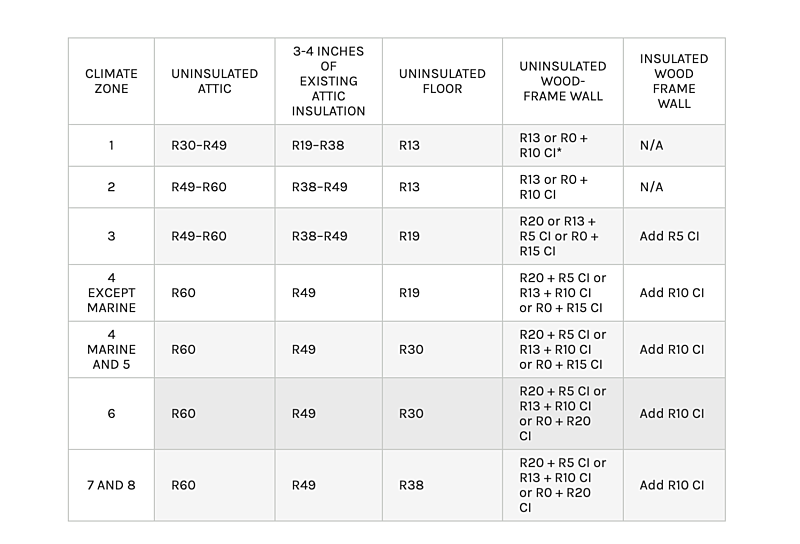

Speaking of targets, what should your target R-value be? Not surprisingly, that depends on where your house is located. The Department of Energy has a set of recommendations based on eight climate zones. Within those zones,

Attic insulation recommendations range from R-30 to R-60.

Floor insulation recommendations start at R-13 and run up to R-38.

Wall insulation recommendations vary depending on exactly where within the walls the insulation is located.

In Pearl’s Home Investment Plans within our Green Door app, we recommend a minimum R-38 for attics in homes in the southern part of the country and R-49 for homes in the northern part. But for my money, unless you’re in Zone 1 (hi, south Florida!), R-60 in the attic is really the way to go to maximize your comfort year round.

How you get there is what we’ll discuss next.

Along with air sealing, insulating your attic or roof plane, walls, and basement or crawlspace is critical to maintaining a comfortable home. But what if you had to choose just one part of your house to insulate? In that case, I always recommend starting with the attic or roof plane.

Why?

If you’ve been following along in this series, you’ll remember I discussed the stack effect in my article on the blower door test. Remember, heat rises and travels from where it’s warmer to where it’s cooler. As heat escapes through an un- or under-insulated attic, cold air is drawn into your home’s lower levels. When it’s hotter outside than in, the reverse stack effect occurs, and hot air enters through gaps in the attic, pushing cold air out of your home and creating a stifling environment. Aside from temperature issues, you’re also kissing your money away in lost energy.

My point is, insulating (and air sealing) your attic is most likely the biggest bang for your buck when it comes to insulating your home. If your attic is taken care of, turn your attention to your basement or crawlspace. Encapsulating and insulating there not only keeps cold, poor-quality air from rising through your floorboards, but also mitigates against moisture accumulation and mold growth.

Encapsulation is the process of running thick, moisture-proof sheeting along the floor and ceiling of the crawlspace. With the sheeting affixed to the wall, moisture-resistant insulation is added in board, batt, or spray form (see Types of insulation material below). Any air vents or leak points are also typically sealed off. The result is improved air quality and more consistent temperatures in your home.

Finally, if you’re looking to truly maximize your home’s potential for comfort, you can opt for insulating your exterior walls. Depending on the age and location of your home, your walls may be uninsulated or under-insulated. Meeting the R-value recommendations from the Department of Energy will, along with attic and basement insulation, effectively create a sleeping bag around your home. I’m talking top-tier coziness.

To get there, however, you’ll have to invest in a costly and labor-intensive process. Your contractor will drill holes between the studs in the exterior walls of your home and blow in loose-fill insulation until it is densely packed. As always, this should be done by an experienced professional in conjunction with air sealing. (You can find a quality Pearl Network Contractor in our free Green Door app.)

Homeowners have a lot of choice when it comes to insulating their homes. From fiberglass to cellulose to spray foam, closed cell to open cell, attic, basement, and wall — R-value might seem like the easiest decision you have to make. There are pros and cons to most of the insulating materials available. In addition to R-value per inch, I always recommend you consider the following factors when making your decision:

Volume: Depending on the material, you may need more or less insulating material to hit your desired depth or R-value.

Space: Insulation needs room to be effective. Certain types of insulation, such as loose fill cellulose or fiberglass, can be densely packed to reach R-values, but only to a point. And others, like fiberglass batts, actually decrease in R-value if overly compressed. Do you have the space necessary to reach your target R-value without crushing that insulation?

Composition: Some newer types of insulation, such as spray foam, emit hazardous vapors that must be fully ventilated before you can re-enter the home. Speak to your contractor and the material manufacturer about their recommended re-entry period before you decide on an insulation type.

Budget: Insulation materials vary based on R-value per inch and material components, which is why knowing your target R-value and the space you need to fill is critical. Your contractor will work with you to draw up an estimate.

Onto the insulation itself! Below are some of the most common insulating materials used in residential buildings. Note that R-values for all insulation materials fall within a range based on manufacturer; what I’ve indicated below is a typical R-value for attic insulation (data source).

Application: Blown-in or batts

Estimated R-value per inch: 2.2-3.1 (blown-in) and 2.9-4.3 (batts)

Far and away the most popular form of insulation for many decades in the U.S., fiberglass comes in batts (sheets) or as a blown-in option. A combination of new and recycled materials like sand, glass, limestone, and soda ash, fiberglass is also one of the most cost-effective options for insulating attics, crawlspaces, and walls. While the R-value per inch of blown-in fiberglass typically tops out at a modest 3.1 in attics, when used in walls, fiberglass can be more densely packed, upping its R-value to 4.6.

Because of its popularity in older homes, it’s important to have your contracting partner examine the condition of any existing insulation in your home. While blown-in fiberglass may not settle — and therefore not lose R-value — to the extent that other blown-in materials do, the existing volume may not meet your target R-value or modern standards. Additionally, contractors can look for evidence of mold or other damage to the insulation that could limit its effectiveness. Your contractor may recommend removing the fiberglass insulation and replacing it, or, layering in more, to achieve your comfort goals.

Application: Blown-in or batts

Estimated R-value per inch: 2.7-3.4 (blown-in) and 3.5-4.0 (batts)

In my time in the energy-efficiency industry, I’ve seen cellulose insulation become more and more popular for its thermal resistance properties, lower cost, and its relatively low environmental impact. Like fiberglass, cellulose insulation comes in both blown-in and batt form and can also be densely packed or combined with a binder for greater adhesion and higher R-value per inch (up to 3.8) for exterior walls. The material itself is nearly all recycled newspaper, with the addition of flame retardants, pesticides, and a small amount of mineral oil added for dust mitigation. In batt form, cellulose may also contain cotton fibers.

As a natural and therefore biodegradable fiber, cellulose insulation does not typically have the same lifespan as fiberglass or spray foam — generally, 20-30 years versus some fiberglass manufacturers’ claims of 70-100 years. (Of course, this all depends on how well you maintain your insulation!) Cellulose may also run a little higher in cost per square foot than fiberglass, but at a higher average R-value, cellulose installation may make more sense for you. As always, your contractor can help you make the best choice for your budget, space, and personal sustainability goals.

Application: Liquid spray

Estimated R-value per inch: 5.8-6.9 (closed cell) and 3.5-4.5 (open cell)

While significantly more costly than the options I’ve already mentioned, spray polyurethane foam, otherwise known as spray foam or SPF, has grown in popularity in luxury new builds and among homeowners looking to create conditioned or finished space in their attics. That’s thanks to a high R-value and air sealing qualities that go beyond what fiberglass or cellulose can do.

The primary chemicals in SPF are mixed with a blowing agent, which causes foam to form and expand; this is done on site. It’s the difference in blowing agents that splits SPF into two categories: closed cell and open cell.

Closed-cell SPF typically uses hydrofluorocarbons (HFCs), while open-cell SPF uses water. The HFCs allow closed-cell SPF to expand up to 50 times in volume, but, as a downside, are high carbon dioxide emitters that contribute to global warming (there are alternatives to HFC blowing agents on the market now, but widespread adoption is taking time).

Open-cell SPF expands to 150 times its volume, making it cheaper to install than closed-cell. Unlike closed-cell, it is water-permeable and has a significantly lower R-value per inch.

From a health and safety perspective, both kinds of SPF emit hazardous chemicals during installation, which is why your contractor will ask you to vacate the home while the foam is being sprayed and is curing and off-gassing. The EPA recommends contacting the manufacturer to get recommendations for when it’s safe to re-enter the home after installation.

If there’s one thing you should take away from this article, and this series, understanding it’s that you, the homeowner, are in control of your environment. Your home shouldn’t be some mysterious box you occupy and make the best of. The tools, materials, and professionals to help you mold your home into a haven are readily available. You get to set your goals when it comes to comfort, health, and energy efficiency. You get to make the decisions when it comes to the timeline and overall spend based on your priorities. We at Pearl and your contracting partner are here to provide guidance and expertise, but ultimately, whether you’re making a series of small changes or transforming your surroundings, you should feel empowered to set your own path to high home performance.

Log in to our award-winning Green Door app to begin building your home performance plan today.